Products

Lastik an Plastic Materials

Consultation

About us

In this section, description of rubber placed.

In case of uncertainty,go to advice section

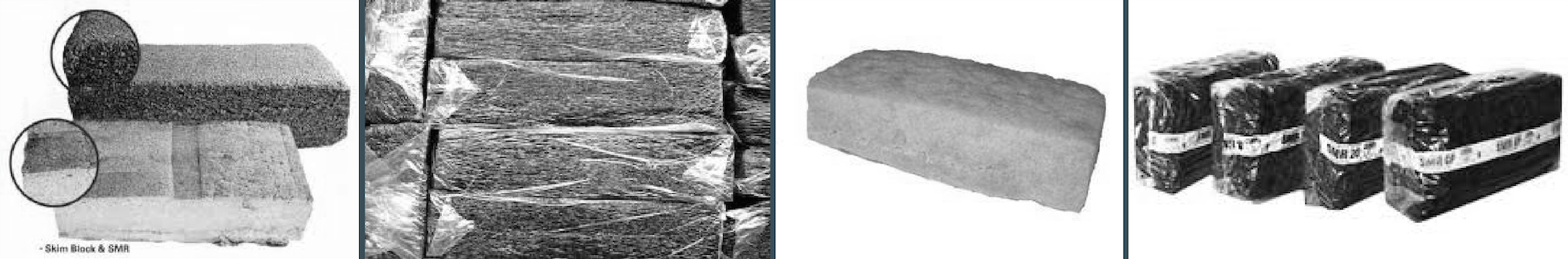

NR

EPDM

SBR

Viton

Advantages:

Low cost, low temperature flexibility, impact resistance, resistance to high shear strength, high resilience, resistance to oil, petrol

Disadvantages:

weak against gases, low resistance to light and ozone, low resistance to flame and ignition

Application:

Of the polymer when cut and abrasion resistance is a growing need to use. The rubber is tough and long wear life and it can be cold at a temperature as low as -45 ° C to work. Application temperature range of -60 to 80 ° C. Car tire, Mechanical, Dampers and glue and ...

Packing:

1Kg, 5Kg, 25Kg, 35Kg

Advantage:

Resistance to ozone, weathering, water, steam, sunlight, abrasion, oxidation, alkalis, solvents, oxygen, plant solvents, acids, trauma, alcohol, growth restriction, compression set good tear strength, impermeability to gases, low temperature flexibility, heat resistance

Disadvantage:

Low resistance to oil and petrol, poor resistance to hydrocarbon solvents, weak adhesion to fibers and metals, poor apparatus property (patches of).

Application:

Car tire, wires and cables, carpets, laminated fabrics, steam hoses for washing machines

Notes:

Available Grades:

Keltan 4802, Keltan 8550(8340A), KEP 270

Packaging:

1Kg, 5Kg, 25Kg, 35Kg

Advantage:

Water resistance, resistance to flexural cracks speciation, oxidation, heat and shock, impermeability, high resilience, high tensile strength

Disadvantage:

Low resistance to ozone, low resistance to ignition, low resistance to gasoline and oil, low resistance to hydrocarbon solvents

Application:

Sheathed cables and wires, conveyor belts, automobile tires, tubes, cloud-like and sponge products

Notes:

Available Grades:

SBR 1500, SBR1502, SBR1712

Package offer:

1Kg, 5Kg, 25Kg, 35Kg

Advantage:

Extremely resistant to strong acids and bases, solvents, ozone is different. It is Resistant to temperatures of 320 ° C and the ignition. In cases where the application of NBR rubber is not possible, oil and hydrocarbon-like environment at high temperature of the rubber used.

Disadvantages:

Low resistance to sunlight and ozone

Applications:

Construction Rollers, O-ring, Sheets, Rubber

Available Grades:

GLT, GBLT, GFLT, A, B, F

Package offer:

1Kg, 5Kg, 25Kg, 35Kg

Rubber Additive

By far the most common vulcanizing methods depend on sulfur. Sulfur, by itself, is a slow vulcanizing agent and does not vulcanize synthetic polyolefin s. Even with natural rubber, large amounts of sulfur, as well as high temperatures and long heating periods are necessary and one obtains unsatisfactory crosslinking efficiency with unsatisfactory strength and aging properties. Only with vulcanization accelerators can the quality corresponding to today's level of technology be achieved.

Types of accelerators include:

These materials form a complex with the accelerator, then increase the curing rate and improve the properties of the final product, the maximum utilization of accelerator systems experience.

These materials raise efficiency with active accelerators. Activators and accelerators can be divided into three categories:

Mineral materials: metal oxides

Zinc oxide

Red Lead oxide

Magnesium Oxide

Lytarzh

Organic materials

Halogenated Stearic acid

Lauric acid

Stearic acid

Oleic acid

Alkalis

These substances increase the PH of rubber compounds and thus increase the curing rat.

DEA

Triethanolamine

The most widely used and the most common curing agent is sulfur reacts with most unsaturated rubber and products vulcanized (network) of it.

A variety of methods exist for vulcanization. A typical vulcanization temperature for a passenger tire is 10 minutes at 170 °C. This process employs the technique known as compression molding. Other methods, for instance to make door profiles for cars, use hot air vulcanization or microwave heated vulcanization (both continuous processes).

Five types of curing systems are in common use. They are:

Sulfur systems

Peroxides

Urethane crosslinkers

Metallic oxides

Acetoxysilane

By far the most common vulcanizing methods depend on sulfur. Sulfur, by itself, is a slow vulcanizing agent and does not vulcanize synthetic polyolefin s. Even with natural rubber, large amounts of sulfur, as well as high temperatures and long heating periods are necessary and one obtains unsatisfactory crosslinking efficiency with unsatisfactory strength and aging properties. Only with vulcanization accelerators can the quality corresponding to today's level of technology be achieved.

Carboxyl rubber, butadiene rubber, and nitrile rubber can react with the carboxyl groups to form cross-links with the process of neutralization of carboxyl groups and the formation of salts done. Poly chloroprene (neoprene), also by reaction with metal oxides such as zinc oxide can be vulcanized. In most systems, metal oxides are used to control the curing rate and absorption of resulting chloride.

Substances that react with the polymer chain, bridge, and with this type of crosslinking, form a three-dimensional network. Epoxy-resin with rubber Nitrile, Dioxime with Butyl rubber and Diamine, or Disulfide with fluorocarbon rubber is used and form three-dimensional bonds.

Organic peroxide is used for vulcanization of saturated rubber or rubber without active groups to form cross-links. This curing agent doesn’t remain in polymer chain, but radical produces carbon bond formation in the polymer chain.

Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of heavy petroleum products such as FCC tar, coal tar, ethylene cracking tar, and a small amount from vegetable oil. Carbon black is a form of paracrystalline carbon that has a high surface-area-to-volume ratio, albeit lower than that of activated carbon. It is dissimilar to soot in its much higher surface-area-to-volume ratio and significantly lower (negligible and non-bioavailable) PAH (polycyclic aromatic hydrocarbon) content. However, carbon black is widely used as a model compound for diesel soot for diesel oxidation experiments. Carbon black is mainly used as a reinforcing filler in tires and other rubber products. In plastics, paints, and inks carbon black is used as a color pigment.

The highest volume use of carbon black is as reinforcing filler in rubber products, especially tires. While a pure gum vulcanizate of styrene-butadiene has a tensile strength of no more than 2.5 MPa, and almost nonexistent abrasion resistance, compounding it with 50% of its weight of carbon black improves its tensile strength and wear resistance as shown in the below table. It is used often in the Aerospace industry in elastomers for aircraft vibration control components such as engine mounts.

| Name | Abbrev | ASTM desig | Particle Size(nm) | Tensile Strength(MPa) | Relative laboratory abrasion | Relative roadwear abrasion |

|---|---|---|---|---|---|---|

| Super Abrasion Furnace | SAF | N110 | 20–25 | 25.2 | 1.35 | 1.25 |

| Intermediate SAF | ISAF | N220 | 24–33 | 23.1 | 1.25 | 1.15 |

| High Abrasion Furnace | HAF | N330 | 28–36 | 22.4 | 1.00 | 1.00 |

| Easy Processing Channel | EPC | N300 | 30–35 | 21.7 | 0.80 | 0.90 |

| Fast Extruding Furnace | FEF | N550 | 39–55 | 18.2 | 0.64 | 0.72 |

| High Modulus Furnace | HMF | N683 | 49–73 | 16.1 | 0.56 | 0.66 |

| Semi-Reinforcing Furnace | SRF | N770 | 70–96 | 14.7 | 0.48 | 0.60 |

| Fine Thermal | FT | N880 | 180–200 | 12.6 | 0.22 | - |

| Medium Thermal | MT | N990 | 250–350 | 9.8 | 0.18 | - |

Practically all rubber products where tensile and abrasion wear properties are crucial use carbon black, so they are black in color. Where physical properties are important but colors other than black are desired, such as white tennis shoes, precipitated or fumed silica has been used as a substitute for carbon black in reinforcing ability. Silica-based fillers are also gaining market share in automotive tires because they provide better trade-off for fuel efficiency and wet handling due to a lower rolling loss compared to carbon black-filled tires. Traditionally silica fillers had worse abrasion wear properties, but the technology has gradually improved to where they can match carbon black abrasion performance.

If you need advice on our products, please fill out the form below.

Our experts will be sent answer to your email as soon as possible.

Soren Chemical Asia Co. with a scientific capital of a group of elites in the country and the investment of "Soren Steel Asia" company was established in 2013. Due to the market needs for steel, first mission of the Soren Chemical Asia Co. is to produce cleaner for steel surfaces and after 3 years of researches with the effective formulations "Manis" was released to the market. Steel is a durable and beautiful alloy with extensive use which requires a reliable cleaner to accents its brilliance and beauty. We believe instead of wasting our precious time on excessive cleaning and washing we must spend more time enjoying beauty, therefore our goal is producing kind of the solutions with less spending time by the best result. In the next step researches on the detergents production for other surfaces started and car washing liquid was produced which eliminated the need for water.

To prove this claim in the provision of high quality goods and services, the efficiency of products has been in terms of non-corrosive and anti-bacterial environment ” in a way that the primary surface features are maintained” approved by the Razi institute of metallurgy and Pasteur institute.

Due to the potential of human capital, our objective point is to produce high quality cleaner and coating for industrial and household use. Investment has also in research and development begun to meet our domestic and foreign consumers and craftsmen’s needs.

We believe by relying on the scientific capabilities of Iranian experts, Organizational culture and principles of customer focus we can emerge the global market. We do our best to become a knowledge-based institution in the field of chemical products, for the Scientific and technological development and compiling of standards based on research and laboratory studies using friendly products for human and environmental health.

No14,Salari Dead end,Salari street,Andarzgoo Blvd,Farmaniyeh,Tehran

021 - 2645 8523 | 2645 8718 | 3661 6691 | 3399 3182 | 3399 3075